Arrhenius: Repsol's calculator to measure its lubricants' carbon footprint

Where the fight against climate change and reducing greenhouse gas emissions have become global priorities, Repsol has taken a great strides in developing Arrhenius, an innovative carbon footprint calculator for lubricants.

It's name pays tribute to the Swedish scientist, Svante Arrhenius, a pioneer in the study of the greenhouse effect, and allows us to quantify the environmental impact of lubricants manufactured at the Puertollano plant, based on a detailed Life-Cycle Analysis (LCA).

The project started in 2020 and is led by Martí Cortada García, Product Design Sr. Scientist at Repsol, and has benefited from a multidisciplinary effort involving various company departments. Although its development was coordinated by Technical Assistance and Development, the Corporate Sustainability, Commercial, Operations, Purchasing, TechLab, Polyolefins, and Safety and Environment teams were involved, as well as the Puertollano plant. External actors were also involved to complete the process, such as the consulting firms ReMa and LRQA.

The result is a powerful tool that not only allows you to calculate the carbon footprint, but also identifies the key points to focus decarbonization efforts on, constituting a key first step on the path towards sustainability.

In this interview, Martí Cortada García Para offers a more detailed overview of Arrhenius, explaining in depth how it works, the challenges faced during its development, and the importance of this initiative in Repsol's decarbonization strategy.

How did the Arrhenius calculator project come about?

The project emerged in 2020, due to the need to transform our businesses and processes to adapt to the environmental commitments demanded by society. Initially, the scope was limited to calculating the carbon footprint of just a few products, but in 2021, the calculation method was systematized and extended to the entire portfolio.

Why the name?

After the famous Swedish scientist: Svante Arrhenius, who, in 1896, wrote an extensive article on the potential impact of CO2 concentration in the atmosphere on global warming, being one of the first to interpret the greenhouse effect of this gas.

As this calculation tool aims to quantify the CO2 footprint of lubricant products, I thought it would be a nice homage to one of the most important scientists of all time.

How does Arrhenius work?

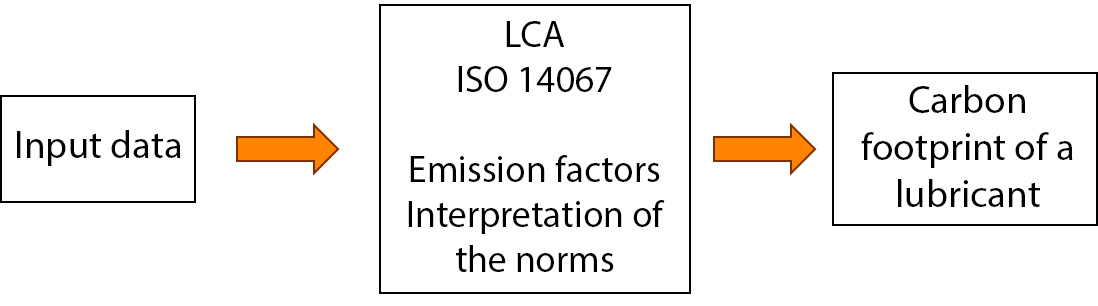

Arrhenius is, basically, a calculation tool that allows us to quantify the environmental impact in kg CO2 equivalents of our lubricant products manufactured at the Puertollano plant.

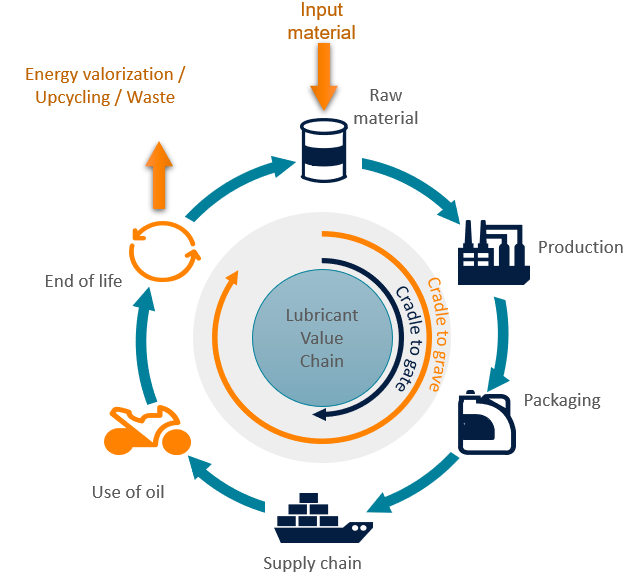

Arrhenius' starting point is the Life Cycle Analysis (LCA) of a group of specific lubricating oils (the Master range) and the ISO 14067 norm. These two pillars help determine all those processes and elements that have an impact, both directly and indirectly, in the manufacturing, marketing, and even any product's end of life and allow its quantification through emission factors.

Each stage contains several elements that must be quantified, such as the carbon footprint of the raw materials, which also includes their packaging and transportation to the lubricant factory. Once each of the previous elements has been quantified, the carbon footprint of any product can be calculated. Logically, the higher the input data quality, the more reliable the results.

What is your role in this project?

This has been a multidisciplinary project involving many people from Repsol, from colleagues in the Sustainability area, to Production, Technical Assistance, and Technology.

We have also had the support of experts outside of Repsol. The consulting firm ReMa has helped us ensure the correct interpretation of the ISO 14067 norm and prepare a detailed LCA. We also had the external verifier, LRQA, to certify the entire process, the data quality, and the veracity of the results obtained.

My role in this process has been to lead the project, from Technology, as well as develop the calculation tool that allows this methodology to be generalized and accelerate the scaling from a few products in the Repsol Lubricants catalog to several hundred.

What has been the main challenge for development?

I think there have been several important challenges, but I'll mention just two. The first and perhaps least obvious is the need for coordination with the different raw material suppliers. Without their collaboration and willingness to work on similar projects, we would never have obtained quality data for the final results.

Another huge challenge we encountered was the lack of specificity in the ISO 14067 norm. This could be an advantage, but in order to obtain consistent results for the industry, all actors, including competitors, must agree on how to interpret the regulations. Along these lines, both API (the American Petroleum Institute) and ATIEL (the Technical Association of the European Lubricants Industry) together with UEIL (the Union of the European Lubricants Industry), developed their methodologies for calculating the carbon footprint, based on ISO 14067 and giving guidance on how to interpret the most conflictive points.

These methodologies were published throughout 2023 (API TR 1533 and “Methodology for Product carbon Footprint Calculations for Lubricants and other Specialties” by ATIEL and UEIL). It should be remembered that we started the project in 2020, and we had our method implemented by 2021. In 2022, we had already managed to develop Arrhenius and extend the calculation to several hundred products.

Why is this project important?

The importance of this project is huge, as it is the first step on the path towards decarbonization. In order to reduce carbon emissions, you must first know your starting point and be able to identify pain points, and in turn, improvement points. In other words, each stage of a product's life cycle must be quantified to know where to make special effort and dedicate resources to effectively reduce the carbon footprint.

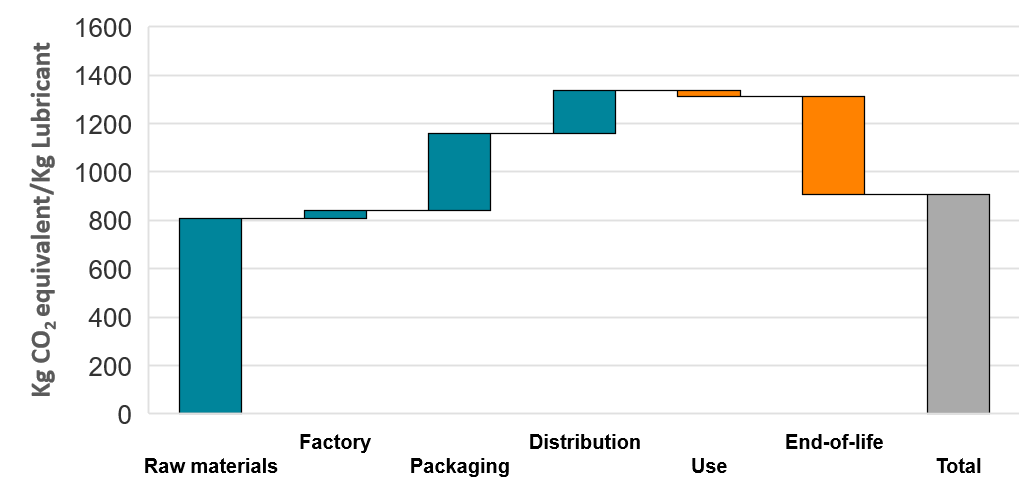

As an example, here is a possible breakdown of the carbon footprint of a model lubricant:

Based on this information, it is clear where we need to dedicate our efforts to decarbonize our portfolio. From most to least relevant:

- Use of more sustainable raw materials.

- Use of more sustainable packaging.

- Continue supporting good practices that allow materials to be recovered at the end of their useful life.

- Decarbonization of logistics.

All this invaluable information would have been impossible to extract without this project.

When did Repsol start using using this calculator? And for what type of tasks?

Repsol has been using this tool informally since its completion in 2022. In 2023, this tool was verified by an external and globally recognized verifier such as LRQA, to make sure the data obtained with Arrhenius has a demonstrated and audited robustness. Since then, it has been available to any customer who considers the carbon footprint an important parameter when deciding which product to purchase. You just have to request it from your sales representative.

What are the future plans for Arrhenius?

The future plans for Arrhenius are clear: integrate the calculator with other digital tools at Repsol and extend it to other production centers of the company.

Related content