Additives in lubricants: small ingredients, great results

When we think of a lubricant, we usually imagine it as a homogeneous fluid that reduces friction and protects the moving parts of an engine or machinery. However, hiding behind that simple appearance is a complex chemical formulation in which additives play a fundamental role. These components are responsible for ensuring that a lubricant can offer superior performance, adapt to extreme conditions, or guarantee the equipment’s durability.

In this article, we will explain what additives are, their main functions, and how they make a difference when it comes to improving lubricants.

What are additives and why are they so important?

Additives are chemical compounds that are added to the base oil to improve its natural properties or provide it with specific characteristics that make it more efficient and versatile. In other words, they are the secret ingredients that turn a simple oil into a high-performance lubricant.

Although their proportion in the formula is usually small (an additive package can have a proportion between 5% and 30%), their impact is very significant, since each type of additive fulfills a specific function. Thus, their combination allows the lubricant to respond to the needs of different applications, from high-powered engines to complex industrial systems. In addition, thanks to the additives and the synthetic bases, the useful life of the oils can be extended, extending the change intervals.

Main functions of additives

Additives can be classified according to the functions they perform for the lubricant. Here we highlight some of the most relevant ones:

Anti-wear protection

One of the biggest challenges in any mechanical system is frictional wear between metal surfaces. Anti-wear additives contribute to the formation of a protective film on these surfaces. This way, they reduce friction and, consequently, prolong the life of the components.

Thermal and oxidative stability

At high temperatures, oils tend to degrade, losing their properties and generating harmful residues. Antioxidants and thermal stabilizers prevent this degradation, ensuring that the lubricant maintains its effectiveness even in extreme conditions.

Corrosion prevention

Moisture and acids generated during engine operation can cause corrosion of the metal parts. Corrosion inhibitors neutralize these harmful agents, so they protect the engine’s metal parts.

Deposit control and cleaning

Over time, engines and systems accumulate debris such as soot, varnishes, or sludge. Detergents and dispersants present in lubricants help keep surfaces clean, preventing deposit formation and particle agglomeration that can affect performance.

Viscosity index improvers

A good lubricant must be able to flow properly at both low and high temperatures. Viscosity index improvers allow the oil to maintain its ideal consistency over a wide temperature range for optimal lubrication at all times.

Prevention of foam generation

In some systems, such as hydraulics, the formation of foam can reduce the efficiency of the lubricant due to the presence of air bubbles in the circuits, which prevents the lubricant from operating under optimal conditions. Anti-foam additives control this phenomenon and ensure stable operation.

The science behind additive formulation

The development of additives is not an easy task. Each component must meet strict quality and compatibility standards to ensure that the lubricant works optimally. In addition, the combination of different additives requires a precise balance: too much of one can interfere with the effectiveness of another.

For example, a lubricant designed for an internal combustion engine must balance properties such as wear resistance, cleanliness, and thermal stability, while an industrial oil may prioritize corrosion protection and the ability to withstand heavy loads. This delicate balance is the result of years of exhaustive research and testing.

HInnovation in the development of lubricants

There's more to every drop of lubricant than just chemistry: there's science, technology, and an unwavering commitment to excellence. That's why innovation is key to staying ahead. At Repsol Lubricants, we have adopted advanced technologies such as artificial intelligence (AI) and robotics to transform our formulation development and optimization process.

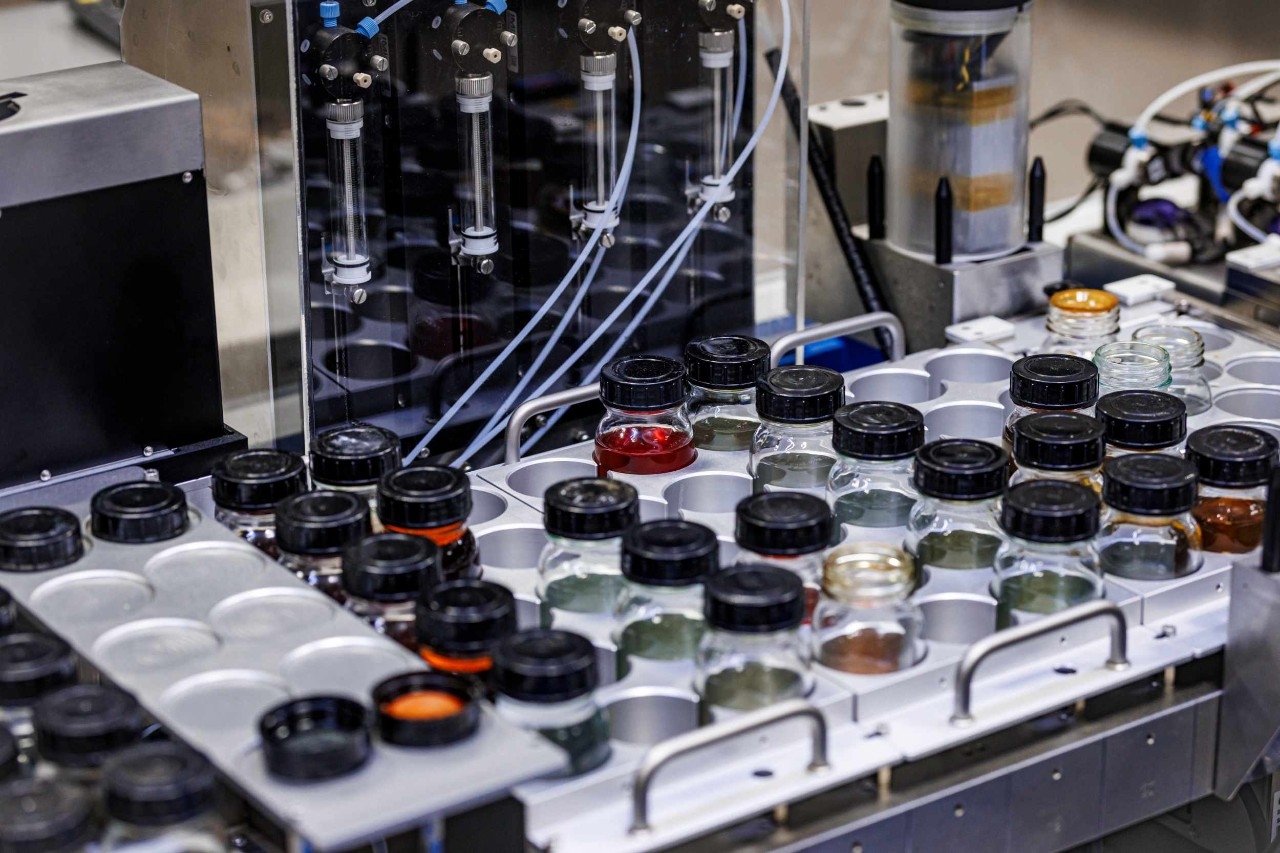

Automation and sample analysis

Thanks to robotic systems, we can now automate sample preparation and testing. This allows us to simultaneously analyze a large number of formulations with small variations, allowing us to quickly identify the optimal combination of additives for each application. This approach has increased our development capacity sixfold, significantly accelerating the time it takes to bring new products to the market.

Prediction with artificial intelligence

AI also plays a crucial role in enabling us to predict the behavior of new raw materials, including innovative additives and sustainable materials such as those derived from waste. This predictive capability helps us design more efficient lubricants without the need for physical testing and with resource optimization.

Related content