"The big challenge is to make all our lubricants of renewable origin"

Francisco Sanz, Product Design Senior Scientist at Repsol Tech Lab, is a clear example of how science and innovation can converge to address sustainability challenges. With a solid academic background and a professional trajectory marked by applied research, Sanz leads key projects in the development of fuels and lubricants that seek to adapt to market demands and contribute to the company's goal of net zero emissions.

His career began at the Universidad Autónoma de Madrid, where he studied chemistry. After completing his degree, he worked at the fuels and petrochemical laboratory at the Universidad Politécnica de Madrid, which marked the beginning of his specialization in the area. "When I finished, I went to work in the fuels and petrochemical laboratory at the Politécnica and, once there, I decided to do my Master's degree in Environmental Risk Modeling and Analysis," he explains. These studies opened the door to a PhD, which culminated in 2017 with a thesis on biodegradable oils for dielectric applications.

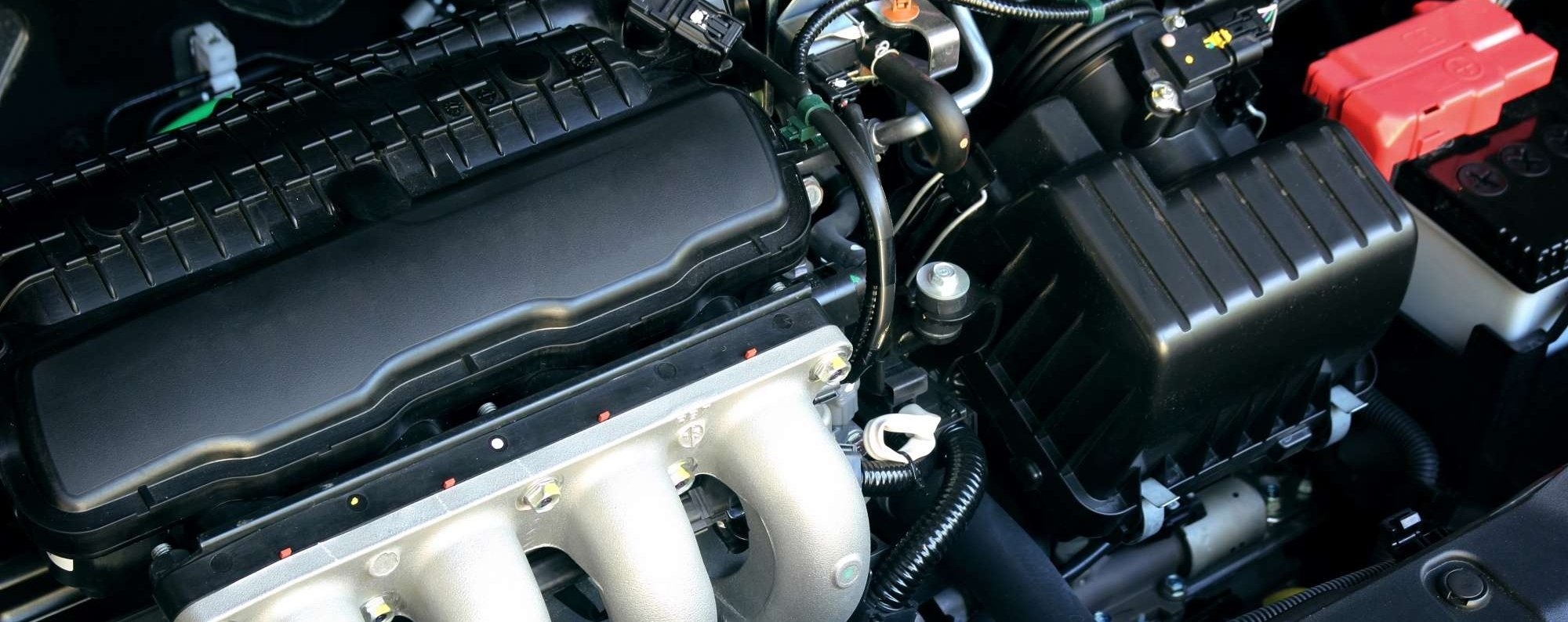

Today, Sanz works as a Product Design Scientist at Repsol TechLab's formulation laboratory, where his team develops fuels and lubricants. "Our main job is to design and evaluate formulas according to new specifications and technologies," he says, adding: "Both the metallurgy of engines and industrial assets is changing. The geometry and efficiencies are much more demanding and, therefore, Repsol's fuels and lubricants have to adapt."

One of the pillars of his work is sustainability, as he is involved in three strategic projects within the Product Design department. The first seeks to improve the energy efficiency of industrial lubricating oils by evaluating their performance in different contexts. Another is focused on expanding Repsol's catalog through new applications.

Thirdly, there is the project to develop biobases to obtain the biolubricants of the future. "The company's goal is to be net zero emissions by 2050. To do this, we have to change our entire portfolio of fossil-based lubricating oils to biolubricants," he explains.

Biobases can be produced in three main ways. The first uses renewable hydrogen obtained by electrolysis of water and combined with CO2 captured from the atmosphere to produce synthetic lubricants. Another option is the use of methanol obtained from sugar cane, which after a dehydration process gives rise to synthetic group IV bases. Finally, used cooking oils are also being used which, after being hydrogenated, generate light bases for industrial oils. "From there we create biobases that we are going to be able to use for our oils," he details.

Sanz's career highlights the crucial role of scientific research in a context where sustainability is no longer an option, but a necessity. In fact, when asked about the biggest challenge for his team, Sanz is clear: "To modify and transfer our entire portfolio of fuels and lubricants from mineral origin to renewable origin."

Related content