Putting our lubricants to the test: how motorcycle oil performance is analyzed

Innovation and quality are two pillars of our work at Repsol Lubricants. To ensure our products meet the highest standards and offer the best performance in real-world conditions, we regularly conduct field tests. These tests are essential in validating oils already on the market, but also evaluating new formulations, providing crucial information on how they behave in different vehicles and circumstances.

In recent months, we have been carrying a field test in collaboration with the CMT Institute (Clean Mobility & Thermofluids) of the Universitat Politècnica de València (UPV). This joint effort allowed us to access a diverse sample of motorcycles to test our products, obtaining representative results of the current fleet.

Rigorous methodology for reliable results

The collaboration with the UPV was key to the test's success. Their team was in charge of recruiting participants, looking for a varied representation of 4-stroke motorcycle models and displacements, with a total of 20 participants. Valencia was as a strategic choice, due to the popularity of motorcycles in the city, which allowed the tests to be carried out under normal use conditions.

The change process was standardized to ensure the consistency and reliability of the results All participants attended the same workshop, where samples of the used oil were taken before the change. The workshop also received a materials supply to carry out this collection, following a specific protocol that guaranteed the process's quality. This step allowed us to evaluate the initial condition of each engine and detect any potential problems, such as the presence of wear metals, fuel or oil degradation.

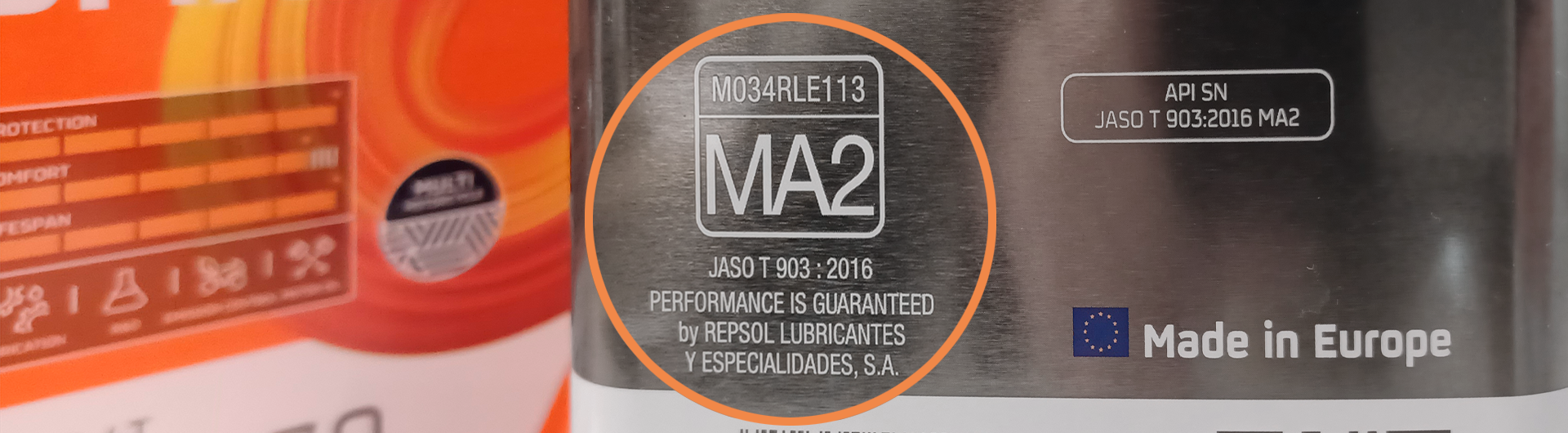

Different oils from the Repsol Racing and Smarter ranges were then tested, covering a wide array of formulations and viscosities. Initially, a sample was taken after 20 minutes of engine operation to obtain a reference for the new oil in use, taking into consideration the inevitable mixture of previous oil with residues in the crankcase.

Two additional samples were collected: one at the beginning of summer, after four months of use, and another at the end of the summer period. A questionnaire was also carried out for each user to collect information on mileage, periods between oil changes, possible breakdowns, and other relevant data.

Comprehensive analysis and conclusions

After the field tests, samples of the products used were analyzed to evaluate key parameters such as viscosity, density, oxidation, acidity, the presence of metals or possible contamination with water. The aim was to observe the oil's behavior in each engine and detect any possible anomalies that could indicate a problem.

The results showed that viscosity and wear and tear values remained within normal ranges in most motorcycles. The variations observed in some cases were due to factors other than the oil and had been previously detected in the initial samples. The loss of additives, oxidation, and nitration also showed normal behavior.

This field test confirmed the effectiveness of the Repsol Racing and Smarter formulations on a variety of motorcycles and conditions of use. In addition, the collaboration with the Universidad Politécnica de Valencia served to strengthen ties with the academic community and obtain valuable information to develop our products.

Related content