Repsol Health, Safety, and Environment Policy, a solid commitment

Management of Repsol lubricant and quality systems

Repsol has demonstrated its commitment to excellence in the management of its lubricant and quality systems, as well as in all aspects of its business, which has been consolidated by obtaining and maintaining all the necessary ISO certifications over more than two decades. .

Since 1994, the company has worked diligently on the implementation of a robust management system that guarantees high quality, safety, and environmental levels. The organization integrates these and energy efficiency standards into its system, ensuring that it is always in line with global management system requirements.

Repsol's commitment to continuous improvement is key to its success, as the company continually focuses on identifying possible areas of improvement, in order to guarantee customers products of the highest quality and safety.

Certifications obtained by Repsol Lubricantes, Asfaltos y Especialidades:

In the automotive world, Repsol Lubricantes has the most stringent quality certifications, proof of its ability to comply with the most rigorous requirements in the industry.

Repsol Lubricantes, Asfaltos y Especialidades’ ISO 9001, IATF 16949, ISO 14001, ISO 50001, and ISO 45001 certifications are proof of the company’s commitment to quality, the environment, energy efficiency, and occupational health and safety.

The maintenance of these certifications strengthens Repsol Lubricantes’ position in the market, as customers can have complete confidence in the quality of its products and in its ability to comply with the sector’s highest standards.

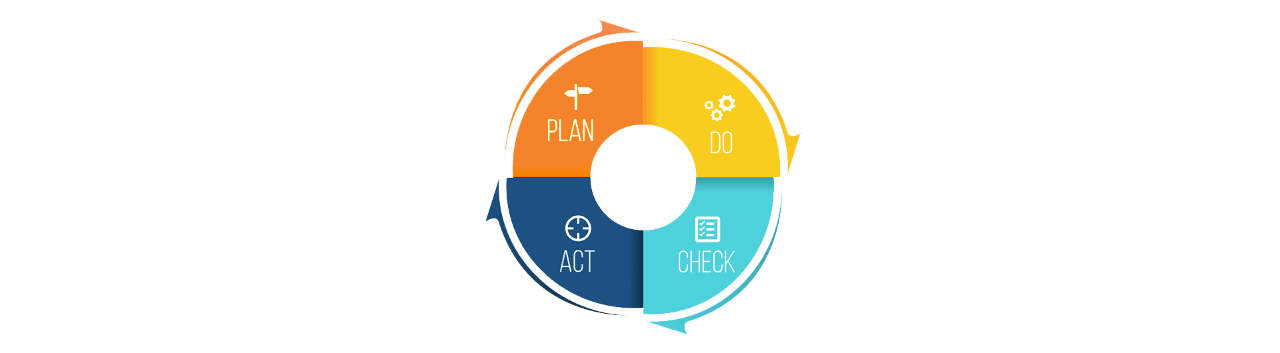

A management system aligned with the PDCA cycle (Plan-Do-Check-Act):

In an increasingly changing and unpredictable environment, with high levels of competition, organizations must adapt to several challenges of continuous improvement and development. To this end, Repsol Lubricantes, Asfaltos y Especialidades (RLESA) applies tools that promote its constant evolution, in order to ensure our customers’ satisfaction.

One of these tools is the PDCA cycle (Plan-Do-Check-Act), with which our management system is aligned, due to its efficiency, as it is a dynamic and flexible model. Based on this cycle, each of our processes and operations can be managed in such a way that improvement actions are continuously generated.

- The importance of this cycle lies in its potential to help reduce costs, improve productivity, and ultimately contribute to the business’ survival in a market that is constantly changing and allowing us to grow every day as an organization focused on quality.